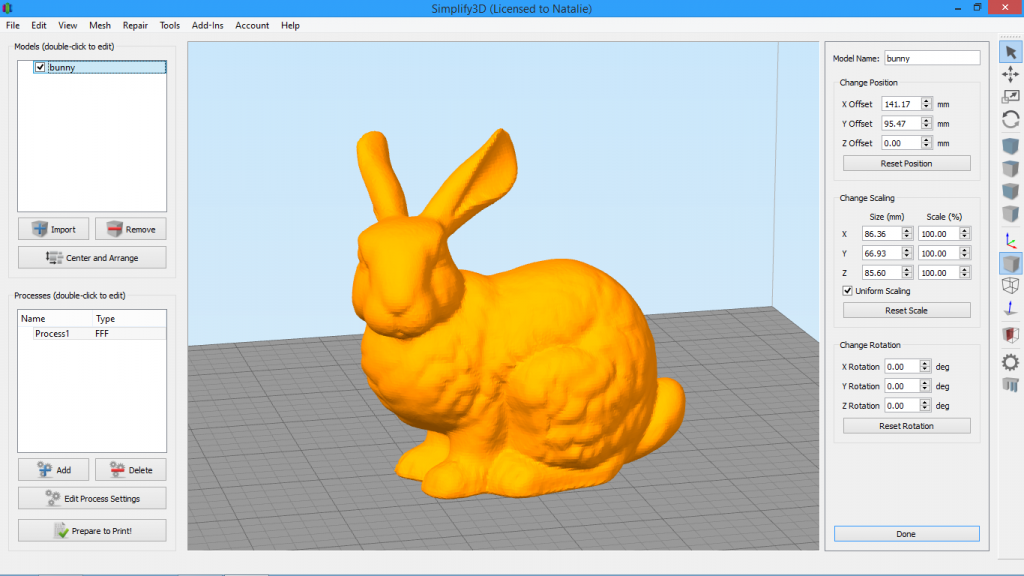

Profiles store everything from the size of the print bed to the temperature for a particular filament. Profiles are where the bulk of configuration settings are stored in Simplify 3D. Preparing to print the Starlink Adapter in Simplify 3D Profiles What settings are included in material settings vs profile settings? What is the relationship between profiles and processes? And what do I need to do when adding a new printer? In this article, I set out to answer these questions by experimenting with real examples in Simplify 3D (I used version 4 in this post). Even though there are Simplify 3D videos about profiles, processes and material / quality settings, I still had a lot of questions. Specifically, I realized I've never fully understood the difference between process, profile, material, and quality settings in Simplify 3D.īased on the number of discussions on this topic in the Simplify 3D forums, this also seems like a confusing topic for many Simplify 3D users. And with spending so much time modeling, slicing, and printing, I've realized there are still some features of Simplify 3D that I don't fully understand. And also purchased a second 3D printer to keep up with demand and enable printing larger parts. But I've mostly used it for one-off prints, slicing a 3D model to make a single print and then moving on to another project.īut I've recently been printing a lot of Starlink Tripod Adapters which I've been selling on Etsy. Simplify 3D has been my go-to 3D printing slicer for many years. As you can see the text isn’t there and my print will sit flush on my print bed.Understanding the difference and how to use process, profile, material, factory, and quality settings in Simplify 3D version 4. I then click on “Prepare to Print” and slide to the bottom layer. I then go into my Process settings –> Advanced Tab and check “Start printing at height:” and set it to. You will see below that I moved the Z-Axis to. The first thing you have to to is find out how far inset the text is by using the cross section dialog in Simplif圓d It won’t have the nice bevel on the top, but that’s okay with me. It will actually print fine, but I would just prefer it sit flush. Here’s what the bottom of the model looks like:Īs you can see, that inset text prevents the part from sitting completely on the bed. Instead of trying to modify it in Fusion 360, I’m going to use Simplif圓D to tell my Dremel to start printing the model after the inset. I would rather the entire bottom of the piece be flush with the print bed. I’m printing out part I found on Thingiverse and the bottom of it has some inset text.

0 kommentar(er)

0 kommentar(er)